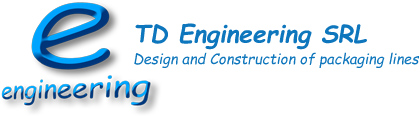

Alternating or continuous doser and capping machine, fully electronic for the dosage of foamy liquids, creams and gel.

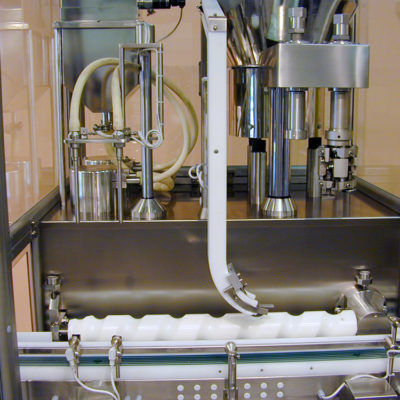

Control panel with touch screen for machine/operator dialogue that allows the storage of production cycles in specific recipes, eliminating the traditional change of size via syringe valve.

Equipped with DLP-patented dosing system that offers a dosage precision of +/- 1.00%.

All the parts in direct contact with the product are created in AISI 316L stainless steel and the silicone neoprene tube is certified.

Possible capping operations:

- Pressure

- Screw on

- Pilfer-proof

- Flip-off

- Locking ring

Machine structure

- In aluminium with protection casing in stainless steel AISI 304

- Levelling anti-vibration feet

- Protection hood in polycarbonate with double-contact micro-switch.

Equipment on demand

- Glass protection hood

- Explosion-proof system

- Laminar flow

- NN DLP dosers according to the productions and the product to be processed

- Tank realised in stainless steel AISI 316L

- Nozzle impact control

- Sterilization program for all the parts in contact with the product

- Automatic feeding under-caps and/or caps

| TMLS ECO | TMLS MED | TMLS STD | |

|---|---|---|---|

| Minimum container dimensions (mm) | Ø25xH40 | Ø25xH40 | Ø25xH40 |

| Maximum container dimensions (mm) | Ø100xH280 | Ø100xH280 | Ø100xH280 |

| Single-dose | No | No | No |

| Maximum speed (pc/hour) | 2500 | 5000 | 7500 |

| Overall dimensions (mm) | 2200x1040x2000H | 2950x1040x2000H | 3700x1040x2000H |

Alternating and continuous block machine video